You can locate this metal Guide by looking behind the white plastic bill guide attached to the lower portion of the head.

The next step would be the guide that the wiper blade passes through on its way to the Velcro plates. If you find any of these then replacing the wiper blade would be an excellent choice. It is important that it does have a slight bow to it, but it is also equally important that their are no other bends into it or dings or dimples of any sort. The next part you need to inspect is the wiper blade itself. And then with a crocus cloth, polish smooth the outside and inside portion of the guide rail. This is a very important part not to loose.

If the guide rail feels pitted or rough, the remove the hex bolt and the white plastic block, are sure to catch the washer. Does it stick? or feel rough? If it does then try slightly loosening that hex bolt just a tad so it can extend more properly without sticking on the rail. Pull the block down and feel how its relationship between it and the guide rail it rides along. It is attached to the linkage by a 7mm black hex bolt. This white block acts as a guide for the wiper linkage descent and ascent. Next is the white silicone rectangle block. The next step is the linkage section, it is attached to the wiper motor shaft and is the main arm that extends and retracts the wiper blade, Look at the connective joints of the linkage parts, their are two arms to it, look for any signs of wear from the elements, look especially at the connection point of the two linkages. There is also a spring that surrounds the shaft of the wiper motor, If this spring is pitted worn down from the elements or has the rust color to it, then it too would be ineffectual in returning the wiper in the up position. There is a shaft that sticks out of the right side of the motor, If this shaft has become worn or has the beginnings of rust wither or the exterior or the interior starting to occur then it would not be effective in driving the linkage down. The wiper motor sits on the left hand side of your machine and it is either square in shape or bronze domed in shape and color. We will start at the wiper motor and go from there. The way in which a wiper works, are several parts working together. Please click on the link below to see the Basic way to resolve a 206 error on your machine.

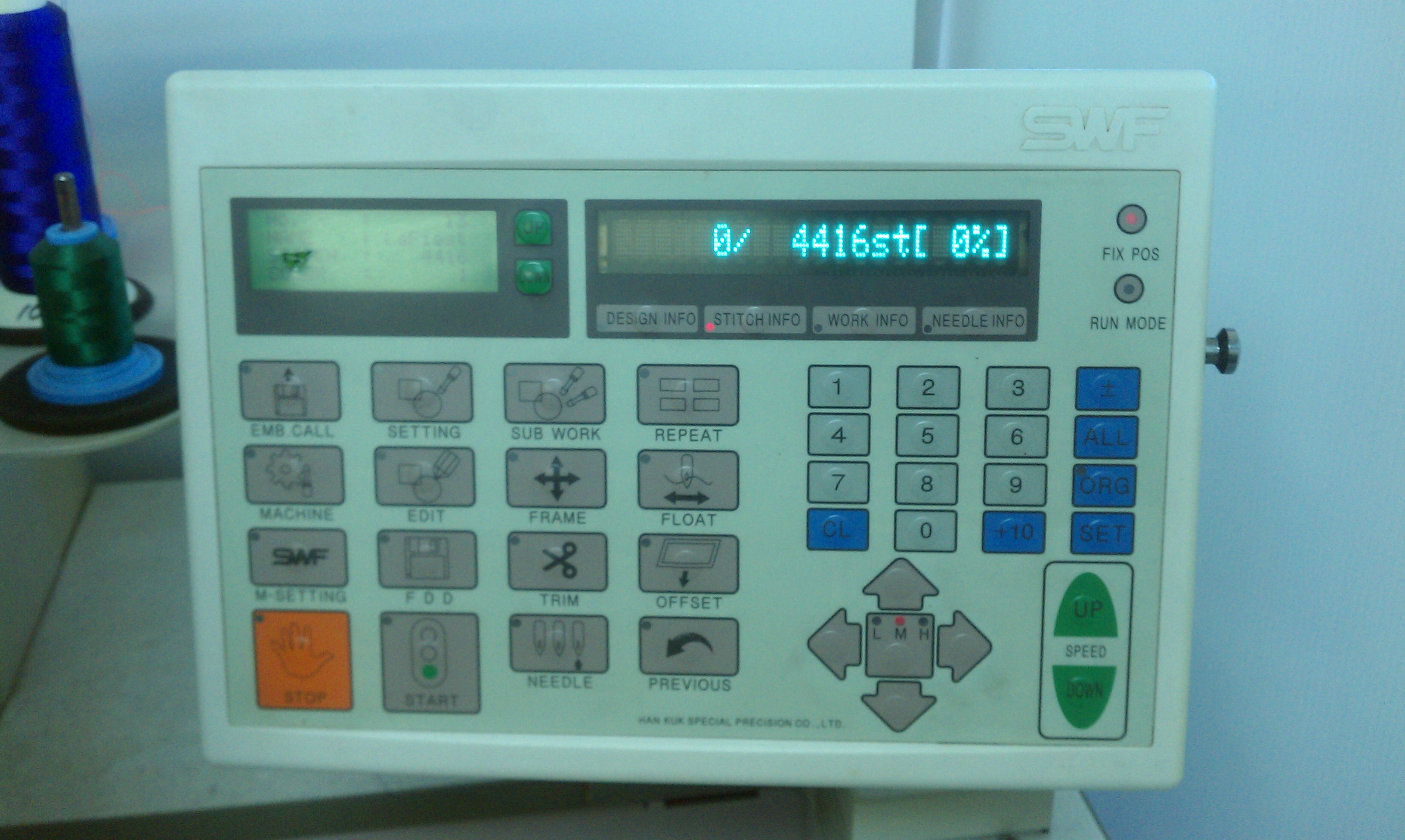

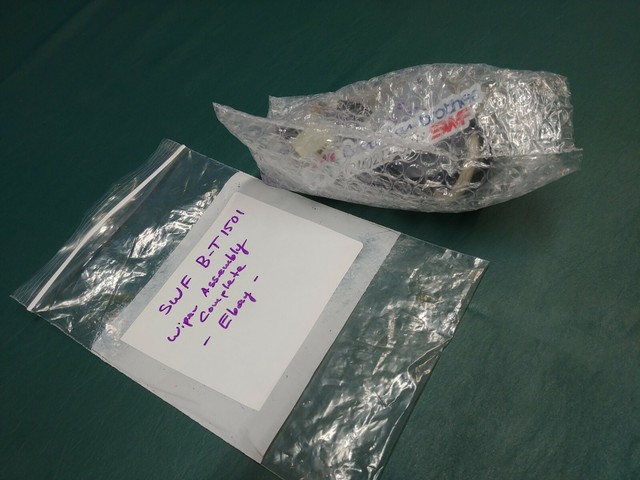

Swf embroidery machine wiper parts series#

If the connection is fine then we have to consider the Joint Board.įor a newer type Single Head machine E-1501C the Joint Board is located on top of the machine in front of the Thread Rack and for an older style like A or B series the Joint Board is located on the rear right side of the machine, please see pictures below:įor a K series machines the Wiper Motor connects to the BACK PLAIN BOARD LIKE THE PICTURE BELOWįor an older type Embroidery machine like Series A or B the Wiper Motor connects to a Joint Board. When the adjustment is done and if the Wiper is not damage then we have to consider a connection issue, locate the Wiper Motor and trace the cable that plugs to the Joint Board and disconnect the plug and connect it back in. We can bend it back to its normal state or replace it if necessary, sometimes is a simple adjustment for the Wiper to get thru the Velcro of the Base Board with no problems, the adjustment is done between the WIPER and the UPPER THREAD BASE SET, the Base set can be adjust it by going up and down to make sure that the Wiper gets through the middle of the Velcro. Below we can see a Diagram of the Wiper for a Single Head machine and for a Multi head machine. The Wiper at its function it gets thru the Upper Thread Base set Velcro, it can get bent or damage. The Wiper is the part that comes out and grabs the upper thread at every trim, the Wiper does not cut the thread the only job of the Wiper is to come out and get the thread out of the working area.

0 kommentar(er)

0 kommentar(er)